PVD Coating Services in India - A&I Vendor

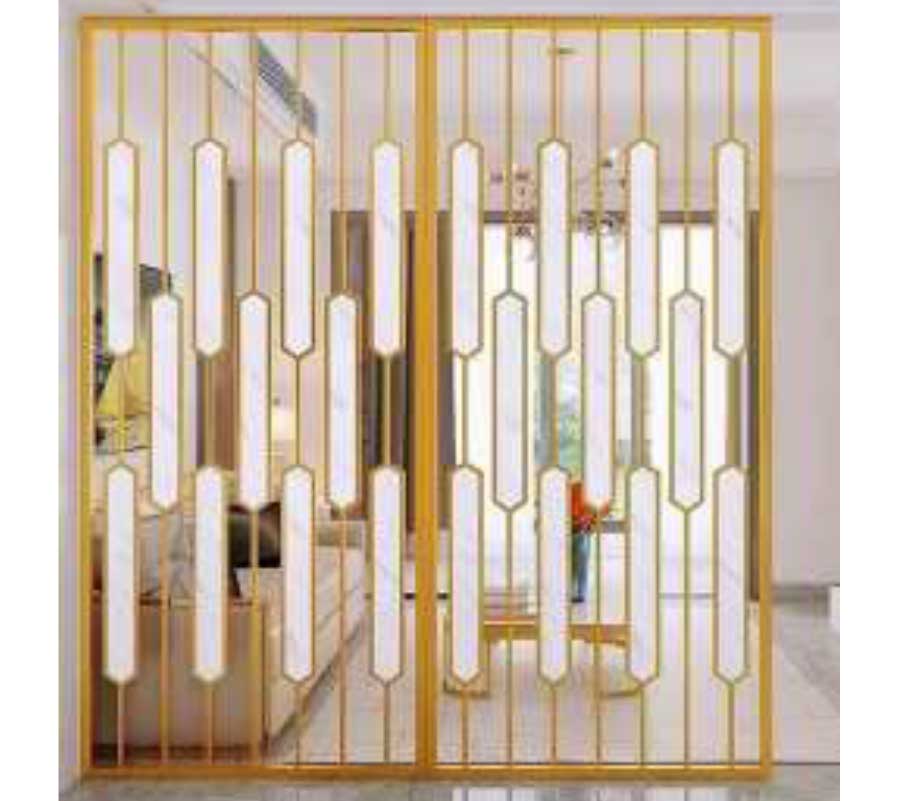

A&I Vendor is the leading provider of Physical Vapor Deposition or PVD coating services in India, delivering cutting-edge surface finishing solutions for residential, commercial and industrial applications. We are also a reliable Decorative Screen manufacturers in India. Chekc once!

Our services that we bring forth are the sought after things for duration, prettiness, and increased performance. PVD coat is the latest technology that comprises the procedure of vaporizing and then solidifying the material in the vacuum onto the surface creating a thin but dense layer. This way markedly increases the wear resistance, hardness as well as corrosion resistance of the coated items which in general makes them applicable in several divergent areas.

Why Choose A&I Vendor for PVD Coating in India?

A&I Vendor aims to provide top-quality PVD Coating

Service Providers in India and is dedicated to furnishing furniture manufacturing

industries. Though the services involve the application of coatings of

chemical compounds such as titanium nitride, chromium, or zirconium with

the result being that usability spans the lightning resilience and the

shiny and modernistic appearance.

From the centre table to railings, our gold PVD coatings being done using

these coatings that helps in your project. What is the centre of

attention, in this case, is the implementation of this method, a

phenomenon that leads to a beautiful finish for objects. This type of

coating is best used when applied to metallic surfaces such as stainless

steel; therefore, a more polished and luxurious look is achieved. With

the help of PVD, now your furniture such as dining tables, canter

tables, partitions, kitchen cabinets, console tables, chairs, bar

chairs, and so on can have a new look that will make your house look

lovelier and more beautiful than it was before.

What is the meaning of PVD Coating?

Physical Vapor Deposition (PVD) coating is a versatile material handling technique that has quite a few upsides to most organizations. This process is implied the physical evaporation and condensation of material from passage to substrate. These kinds of technologies are a double-edged sword as it may detract significantly from the value of products while boosting the efficiency and other characteristics of many hardware. We are a company which is famous for PVD technology as we have the strength and skill to do a good job.

Processes of PVD Coating Services:

Using point-by-point reasoning, we shall examine the basic components of PVD coating and its uses.

- Vaporizing Material: The substance to be used in coating. Metals commonly used for PVD coating include titanium, chromium, aluminum, gold, silver, and platinum. Sometimes, ceramics are added for hardness and wear resistance.

- Vacuum Chamber: The vacuum of PVD prevents the interference of air molecules on the substrate by the vaporized material. This makes a cleaner and harder surface.

- Substrate: The term “substrate” refers to the material or the object that is coated. Substrates can be metallic, glass, plastic, or ceramic in nature. It is typically modified prior to the application of the coating to ensure the great adhesion of the coating to it.

- Energy Source: The role of energy is the vaporization of the material during sputtering (a process in which ions are the ones that eject the material from the target) or evaporation (a process in which the material is heated enough to vaporize it). Heat, electric fields, and lasers are among the variable energy sources that are commonly utilized.

- Gas (If required): In the PVD process, a small amount of reactive gas (like nitrogen or oxygen) is sometimes added. This is done specifically to manufacture compound coatings such as titanium nitride. This modification augments the worn, corroded, or overheated materials venture of the coating.

- Deposition process: This is concerned with the actual deposition of the vaporized material on the substratum. There is the condensation of materials on the surface during the contact, resulting in the formation of thin, hard, and homogeneous coatings over a large area. There are a variety of deposition methods that depend on which PVD method (sputtering, evaporation, etc.) is used.

Applications of PVD coatings:

We provide a wide range of PVD coating services for various residential, commercial and industrial applications. Below is the attached sheet for more clarification.

| Residential | Commercial | Industrial |

|---|---|---|

| Home Furniture | Sporting goods | Automotive components |

| Mirror Frames | Leisure Items | Transport Industry |

| Room Divider or Partitions | Tables, partitions in Hotels | Marine Fixture |

| Kitchen Trolleys or cabinets | Decorative vases | Cutting tools, drills |

| Centre or dining table | Corporate Office | Large Scale Manufacturing |

| Garden Furniture | Eyewear, Jewelry | Die & Tools |

Features of PVD coatings:

As PVD Coating in India, below are some features of it.

- We provide a variety of stunning decorative metal finishes such as gold, rose gold, champagne gold, brass, black, and bronze.

- We produce new durable colored metal finishes through our internal research.

- Our ornamental PVD coatings are perfectly appropriate for various interior and exterior furniture pieces, as well as home design products like bathroom items and accessories.

- Our offered PVD coating services are the ideal option for many applications seeking dependable, efficient, and affordable surface treatment options.

- Whether for practical or aesthetic reasons, A&I Vendor guarantees top-quality outcomes consistently.

Being the recognized provider of PVD coating services in India, At A&I Vendor, we are pleased to handle various projects and products, ranging from extensive production runs to smaller individual orders. For project discussions and designs, feel free to call us.